The importance of adequate packaging/crating of critical spare parts

Industry: mining / mineral processing

Application: grinding mills

Sub-assembly: main bearing insert

Minimal packaging requirements seems to have become the norm as suppliers are reducing their costs to remain competitive in today’s market. Unless requested or specified, today’s packaging will typically be designed for a one-time or one-way use and will not take into consideration any site-specific requirements. Risks of injury to personnel and damage to components can increase substantially when this type of packaging is reused over time to store or reship components out for repair

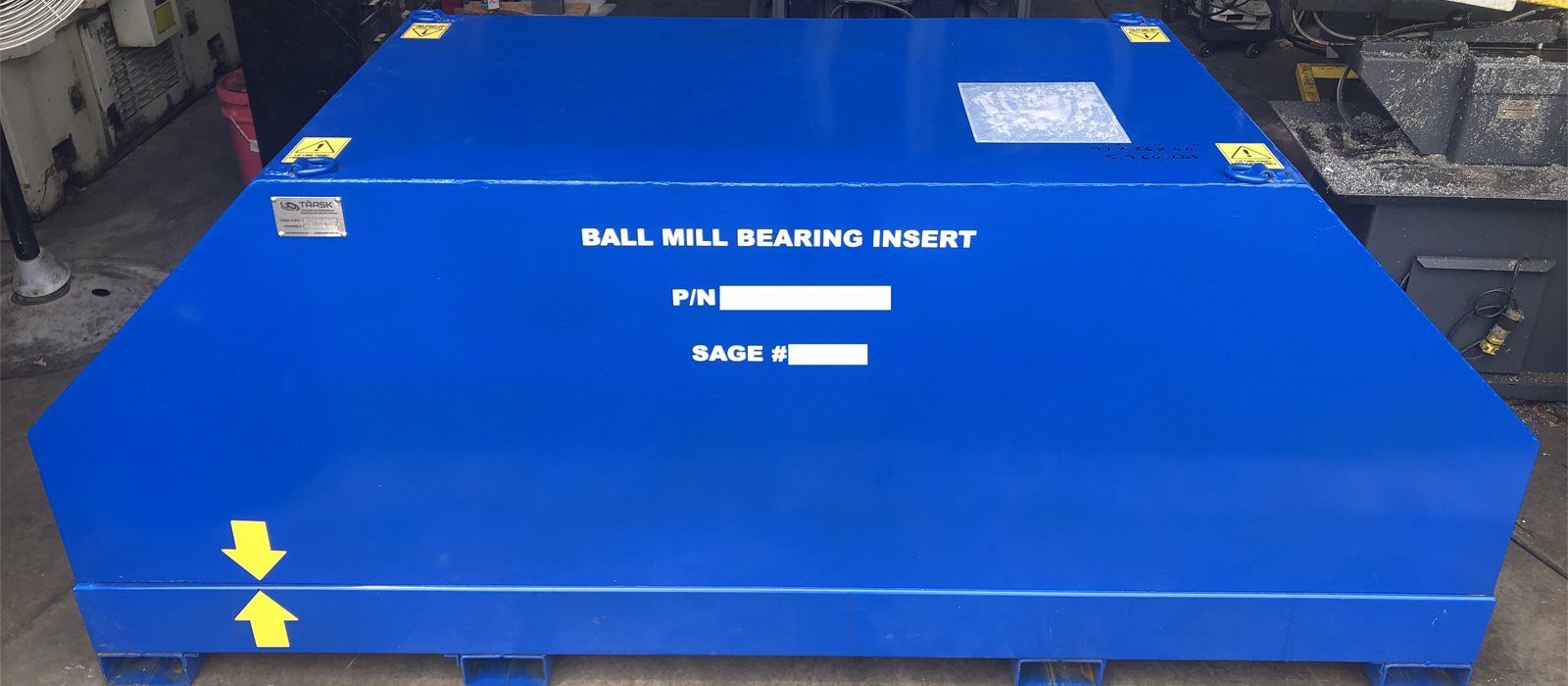

Case Study: Grinding Mill Main Bearing Insert

- A main bearing insert is considered as a critical spare part for a grinding mill, mainly because of the long lead times required to repair or manufacture a replacement. Such bearings are commonly lined with babbitt or bronze, soft alloys which make the part vulnerable to damage if not handled and stored with proper care.

- During a replacement of a main bearing insert for one of our customers, it was observed that the new spare part, weighing around 4000 lbs, had been stored in a poorly built plywood box that was showing evidence of damage and rot. This crating made the spare main bearing vulnerable to damage.

- To address this situation, TÄASK designed and supplied a reusable heavy-duty fabricated steel crate, for shipping and storage of spare main bearings, featuring:

- Excellent protection against physical damage and the elements.

- Secure lifting points, making the crate and bearing easier and safer to handle.

- Bearing orientation (bore side down) for quick servicing, which eliminates additional manipulations during which the part is exposed to damage.

The Bottom Line

Poorly or marginally designed packaging/crating of high value and/or long lead time critical spare parts is a risky practice. The additional cost of well thought out and rugged packaging/crate is minimal, when considering the risks of downtime and loss of production if a critical spare part is damaged during transportation or handling.